What do luxury vehicles and water slides have in common?

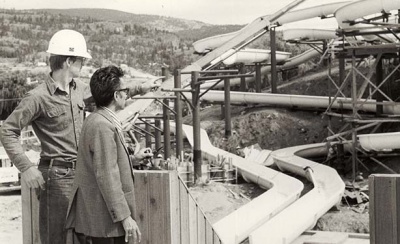

WhiteWater is pleased to announce an exclusive manufacturing partnership with Polmar, which will see the Turkish company produce fiberglass water slides for WhiteWater’s global projects.

Polmar’s parent company, Polkima, are known for their complex molded composite parts and have become the manufacturer of choice for brands such as Volvo, Mercedes, and Daimler. WhiteWater, who also produce fiberglass from their own plant in Canada and have a partnership with a plant in the Philippines, can now manufacture composites on three continents.

As the world has ‘locked down’ due to COVID-19, the benefits of having a global supply chain have become very apparent. WhiteWater’s regional production facilities have helped ensure projects, which are now re-opening in some parts of the world, continue to receive products according to schedule.

“Polmar, as the European production partner, is an important addition to our production capabilities because they exemplify the high quality, consistency, and compliance standards we look for,” said Chief Operating Officer, Onno Meeter. “They are used to meeting the high precision and highest quality expectations of premium car manufacturers, including Mercedes.”

The production facility near Izmir, Turkey, complies with the most stringent automotive standard, IATF 16949, and a number of ISO international standards.

“We value the extension of our relationship with WhiteWater, which enabled us to diversify our work outside the automotive industry, and are confident that the fiberglass innovations and durability enjoyed by our clients, including JCB and Ford, will benefit water park owners too,” said owner, Anthony Gallia.

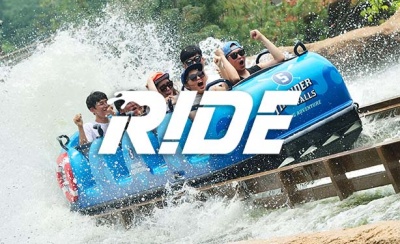

Following thorough auditing of their finances, quality, and processes, WhiteWater started producing slides with Polkima in 2018, and have recently extended their commitment as a partner by investing in a full set of molds to cover all slide part sizes. These brand-new molds make for the most accurate fitting slides and contribute to the unsurpassed quality of the product made from the dedicated line that Polmar has invested in for WhiteWater. This joint investment in these state-of-the-art manufacturing facilities reflects the exclusive agreement that Polmar only make water slides for WhiteWater.

“The extension of our supply relationship with Polmar ensures we continue to be known for the quality and longevity of our fiberglass,” continued Meeter. “From the outset, we’ve been very impressed by their quality control and innovations—they are the only producer in the world that can make 8-millimeter-thick RTM direct from the factory to meet CSEI requirements.”

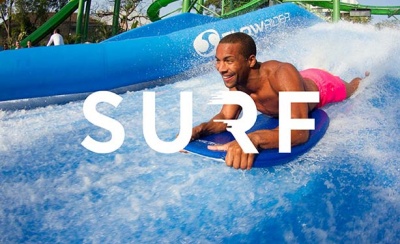

100% of WhiteWater’s product from Polmar is RTM, because the smooth-on-both-sides product is superior to older open mold technology and looks and feels better for riders. WhiteWater appreciates that investing in new products, especially in less certain times like these, mean clients need to be assured that they will receive a product that is a good investment with longevity and ride performance.

“The investment we’ve made in this new plant with Polmar demonstrates WhiteWater’s commitment to consistently produce the world’s best fiberglass slides, wherever they are made,” said Paul Chutter, Chief Business Development Officer. “Our partnership with Polmar ensures that our fiberglass water slides remain smoother, brighter, and longer-lasting than anything else on the market,” he continued.