Net Zero by 2040—Sustainability Scorecard: Manufacturing & Supply Chain

With WhiteWater now placing an urgent focus on sustainability across the water park industry, a corporate-wide, structured approach has been introduced, called the Sustainability Scorecard. Our Scorecard consists of four parts: Corporate, Manufacturing and Supply Chain, Parks and Products, and Social Responsibility. This is part three of a five-part series, which we hope, will motivate players across the industry to take inspiration and join in with their own sustainability efforts.

Halve the waste by 2030, net zero by 2040. It won’t be easy, but we’ve got to try.

The second part of WhiteWater’s Sustainability Scorecard captures all manufacturing and supply chain aspects. This means, we will be working closely with our suppliers to achieve these objectives.

Just like with the Corporate part of our Scorecard, we are approaching these lofty goals by seeking a sound understanding of where we are. What is our current impact on greenhouse gas emissions? How eco-friendly are the materials that we are using? What are we benchmarking against?

Seek Eco-Friendly Alternatives

Even before we have the results of a deep audit, we can do a preliminary assessment so that we can start taking actions that do not require an immense effort but achieve positive effects. For example:

- Eliminating paper in manufacturing. Instead of printing out work orders, fabrication instructions, and drawings, use tablets and computer workstations.

- Identifying harmful materials such as paints, resins, and sealants that can be substituted with more eco-friendly alternatives.

- Reducing the amount of cardboard used.

- Reducing the amount of foam packaging. Use biodegradable packaging instead or something that can be repurposed.

- Using supplies that have more eco-friendly packaging or less wasteful packaging

- Using electric equipment instead of gas-powered, such as EV forklifts.

- Partnering with freight forwarders and other logistics providers who track their CO2 emissions and have sound sustainability policies.

Invest More Now, Waste Less Later

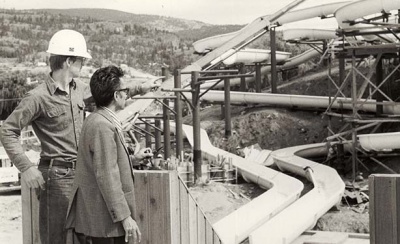

Already, WhiteWater has made the valuable investment to use an automated resin transfer molding system to produce fiberglass parts. This method is very exacting; it uses less material and drastically reduces failures, resulting in much less waste and lower emissions compared to the commonly used “open mold” approach.

Another aspect to consider is using stainless steel in place of galvanized carbon steel. While stainless steel does cost significantly more than carbon steel, it is resistant to rust, will likely last for the lifetime of the water attraction structure, and is highly recyclable.

Make Sustainable Choices at Installation Sites

To finish the manufacturing process, we have construction and installation on site. For each project plan, a recycling and waste reduction policy will be included in the timeline and budget. This means:

- Training site installation advisors to make sustainable choices, reduce waste, and use eco-friendly alternatives.

- Providing different bins for different waste generated on site to promote recycling and re-use of building material.

- Identifying local recycling centers for each material.

- Renting electric equipment and vehicles whenever possible instead of gas-powered.

All these ideas only mark the beginning of WhiteWater’s journey toward net-zero, and we will be taking our suppliers with us. There will be bumps on the way, no doubt, but together, we will keep on going.

In the next blog, we’ll explore the Parks and Products part of our Sustainability Scorecard.

Read more about WhiteWater’s sustainability commitment at https://www.whitewaterwest.com/sustainability.