Recertification Included in WhiteWater’s Slide Resurfacing Service

By Chris Biancofiore, Director, Performance Services

Why is the above even a headline? Because we’ve been noticing that many water park operators do not realize that after a water slide has been resurfaced, it will most likely need to be recommissioned by the OEM. Or they might not realize what exactly is involved in the recommissioning. That’s why we include it in our resurfacing work—to give clients peace of mind.

Let me first explain what water slide resurfacing does.

Resurfacing Is the Last Resort

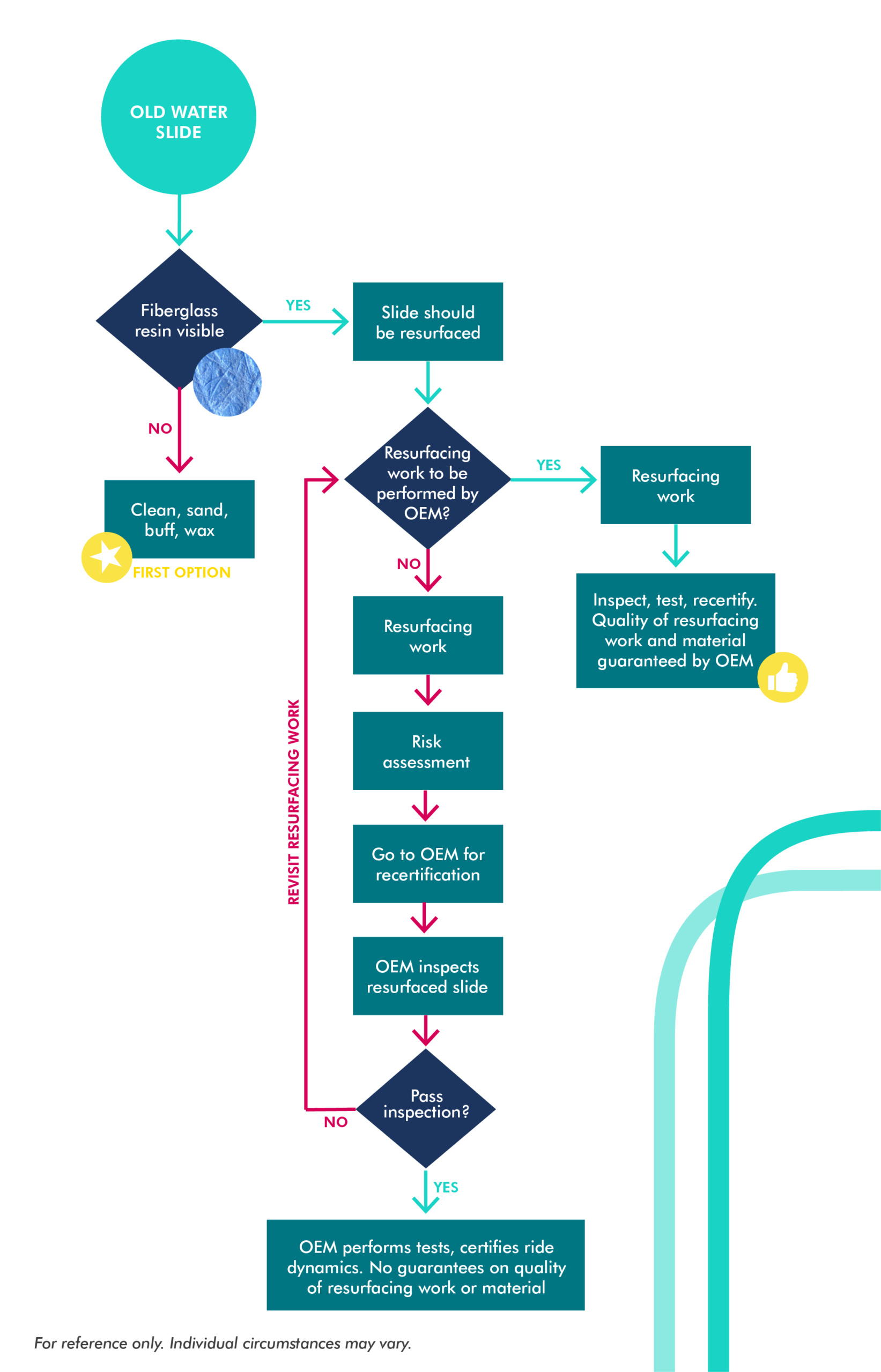

When it comes to water slide maintenance or restoration, cleaning, buffing, and waxing should be the first option, best when regularly performed as outlined in each operations and maintenance (O&M) manual. Old slides can be brought back to beautiful shine just by doing this.

As slides age from friction wear, resurfacing will be required due to the original coating being worn. You want to prolong this for as long as possible because the OEM (original equipment manufacturer) finish will always be the best and smoothest finish, not to mention the unnecessary maintenance cost of resurfacing too soon.

What Happens After Resurfacing?

After a water slide is resurfaced, the operating parameters that were set during commissioning may have to be changed as a result of this work. Resurfacing can potentially affect the coefficient of friction, water flow behaviour, and other ride variables, ultimately affecting the ride dynamics, which concern performance and safety.

When the ride dynamics change, the OEM, as well as many jurisdictions and insurance companies, will deem that a major ride modification has taken place, which requires a recertification, also referred to as recommissioning.

If you have a third party do the resurfacing, a risk assessment should be performed. The result of the risk assessment will likely be that your slide needs to be recertified.

Slide Recertification by the OEM After Third-Party Resurfacing Work

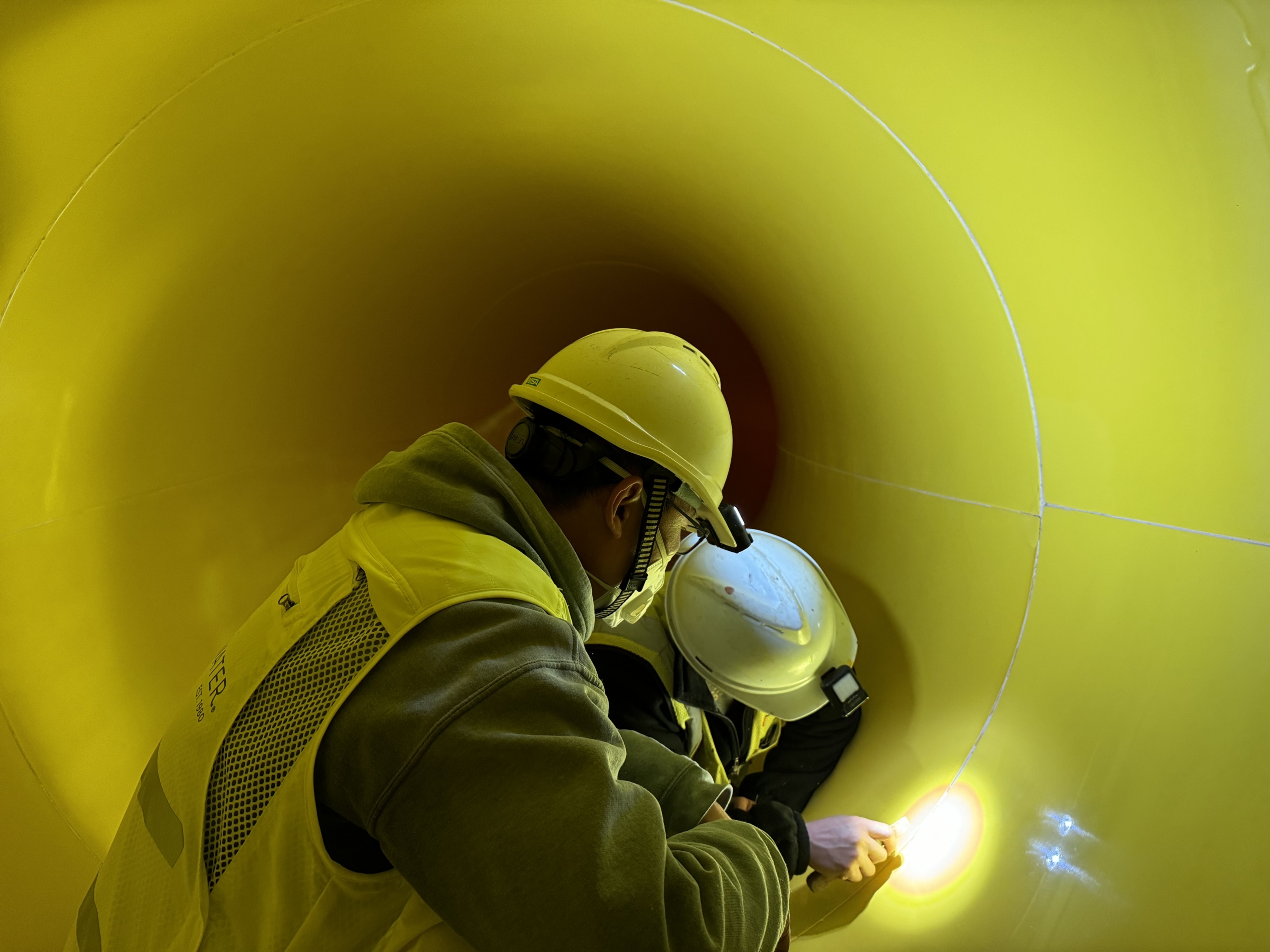

When you call the OEM, i.e., WhiteWater, for recommissioning, the first step of the process includes inspecting that all operating parameters are as per original commissioning. All valves should be locked out and not adjusted unless consulted with the OEM. We can then proceed to performance testing, ascertain if any of these parameters need to be adjusted, and conclude with a written recommissioning certificate for the ride.

In addition, we visually assess the resurfacing work that was performed, and we will require copies of the process and materials that were used. But we only certify the ride dynamics; there is NO representation or guarantee of the quality of the work or the material used, which remains the sole responsibility of the third-party who provided the work.

Recertification Included When WhiteWater Technicians Perform Slide Resurfacing

As the OEM, we know the exact parameters to get your equipment to perform at its best—and the quality of work that would pass the inspection.

Certificate of Commissioning:

To give our clients peace of mind, we guarantee the resurfacing work that we do—including the process and the material—and automatically include the slide recertification service, which involves the following:

Inspection:

- Ride surface condition, water level, flow rate, and ride performance analysis

- For slides with ride vehicles, the vehicle condition

Testing:

- Flow rates and visual assessment of surface condition

- For slides with ride vehicles, visual assessment of vehicle condition and inflation test

- At least 10 test rides of lower, mid, and upper weight limits, maybe more depending on test results and type of ride

- Adjust operating conditions if needed, followed by additional test runs

Upon successful recertification, you will receive a document with critical ride information such as ride ID, operating parameters, inspector name, date, and signature, which should satisfy your local authorities.

If you are not yet familiar with the particularities and consequences of water slide resurfacing and would like to learn more, here are some resources:

Or contact us directly for any questions you may have.