Case Study: Water Slide Tower Replacement in Aruba

Ah Aruba… a sunny paradise with white-sand beaches and turquoise waters.

But if you are operating a water park there, you have to contend with humidity, sand, salt, extreme UV, and hurricanes to keep your facilities worthy of paradise.

In 2025, De Palm Island decided it was time to upgrade its water slide tower and turned to WhiteWater’s Performance Services for a solution.

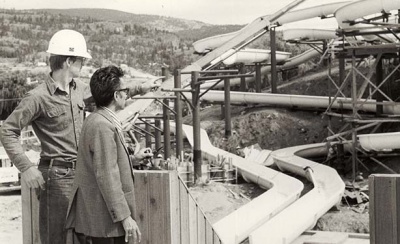

Original water slide tower

Choosing the Original Slide Manufacturer to Perform Tower Upgrade

Owned and operated by De Palm Tours, De Palm Island is a small destination off of Aruba. With overwhelmingly high guest reviews, it offers ample activities, cabanas, food and beverages, and a water park. The landmark of this island is the 20-meter-tall tower, home to two AquaTubes and an AquaLoop with an AquaLaunch capsule.

Initially constructed with concrete stairs and platforms and steel guardrails, the client opted to upgrade the tower to use T1800 protruded fiberglass grating, plastic lumber, and aluminum for improved corrosion resistance.

As the OEM of the slides, with access to the original design specifications and drawings, we knew exactly how to best proceed with the tower refurbishment.

Tower demolition

From Demolition to Rebuild: How We Worked

The team, under the supervision of WhiteWater’s Senior Install Advisor, Wayne, arrived on site in September to begin work, well before the peak holiday season, in close cooperation with the park’s maintenance manager and his staff. With the location being only accessible by boat, logistics for labour and equipment were definitely a challenge and time-consuming—but nothing our team couldn’t handle.

First, the old tower had to be demolished, leaving only the main support columns and bracing. Sara, our project manager, meticulously organized the preparation and execution. Slide entries had to be removed before the demolition, so a crane and a lift were planned in a way that minimized the fiberglass sections needing removal. Extra care was taken for the AquaLaunch, a capsule with a trapdoor and mechatronic equipment.

Through high winds and working from the top down, beams, stairs, and railings were removed within a week. And upon saying “garbage barge” three times, one was summoned to pick up the debris. (We are kidding of course; it’s just fun thing to say.)

The next step for the team was to preassemble the new tower. Extensive carpentry work was needed to cut the plastic lumber planks to fit the structure. Over the next few weeks, the new tower began to take shape. The structural beams, the platforms, the steps of the stairs, and the railing were put together piece by piece, with the help of the crane and the lift.

From Construction Site to Guest-Ready: Slide Recommissioning

When the top platforms were built, it was time to install the removed slide sections and entry boxes and the pickets around them. Extra attention was paid to the mounting of the AquaLaunch capsule as it had a special pedestal and required expert wiring.

After everything was connected—the pump, the water, the power—each slide had to be recommissioned to ensure performance and safety. As the original manufacturer, this was our job. Our team ran a series of tests to confirm the operating parameters.

Only then could the slides be opened to the guests of this private island. For years to come, they will be able to enjoy climbing up the fresh new tower, with beautiful blue pickets along the stairs and comfortable material under their feet, before plunging into water slide thrills.

Looking to upgrade your slide tower? Our Performance Services team will be happy to help. Get in touch here.