Putting the Giant to Bed and Waking It Up: Water Ride Winterization

By Elan Groberman, Performance Services Manager

When all the crowds are gone and the kids are back in school, winter shutdown is top of mind. Whether you are working on off-season storage for just a few weeks or preparing to be frozen solid for months, the following tips listed here are to help you winterize your water ride—log flume, Super Flume, river rafts, Shoot the Chutes, and the like— and get your next season off to a great start.

Not Just Fear-Mongering: What Can Happen If You Don’t Winterize Properly

Of course, the reason amusement parks and theme parks shut down for extended periods is due to the unpleasantries of the cold and precipitation. Freezing, moisture, extended UV exposure, and idleness can lead to expensive ugly surprises come spring.

How?

- Water expands 10% when turning into ice. This generates a lot of force and tends to break things.

- Lots of rain can cause water to pool up, resulting in damage due to the extra moisture and excessive weight on top of equipment.

- Prolonged exposure to the sun’s UV leads to the degradation of plastics, rubber, foam, etc.

- Weeks or months of not moving raises the probability of the ride seizing, losing lubrication, or creating a flat spot.

And we haven’t even started talking about corrosion!

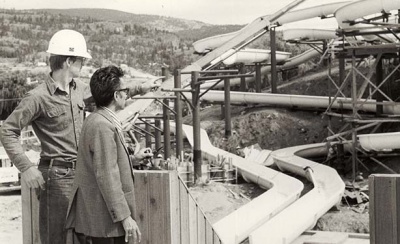

Good news is, all this is preventable if you take the proper measures. With decades of experience supporting water rides around the globe, our team would like to share a few best practices to help you get started.

Run, Test, Record: Establish a Known Condition Before Storage

Before you put your ride to bed, you should determine a baseline. Start by creating an end of season checklist, then:

- Test each function and all sensors.

- Record currents, voltages, speeds, fluid levels, and user settings.

- Thoroughly clean your ride and remove debris (e.g., piles of leaves that can end up creating their own ecosystem, leading to mold, corrosion, and staining).

- Visually inspect your ride and record any repairs needed in the spring.

- Take pictures from every angle, both close up for details and zoomed out for context.

- Remove tension and stored energy, e.g. from hydraulic systems, pneumatic systems, springs, belts, counterweights, capacitor banks, and any other system with potential to harm people or other systems with a sudden release of energy.

Warm, Cozy, and Protected: How to Store Your Ride

If you can, move your ride vehicles into covered storage and lift the wheels off the ground so they don’t develop flat spots. Also try to store any other non-metallics from your ride in covered storage; this includes large items like your conveyor belts. Be careful about putting equipment in steel containers though. The inside can get super hot in the sun and melt plastic and soft goods.

If you can’t move your vehicles into storage, you should cover them up with tarps or industrial shrink wrap like the one you see on boats in marinas over winter. Make sure these can’t flap in the wind or gather pools of water.

Left: Bad tarping job. Right: Industrial shrink wrap.

Not Just for Moving: Lubrication

Grease serves a purpose even though the equipment is not moving. Before you put your ride to bed:

- Ensure all lubrication points are lubricated.

- Wax or use corrosion inhibitor to protect exposed steel such as chains and shafts; pay attention to items that are normally submerged and seeing air for the first time this year.

- Remove chains to store in oil, if possible.

- Ensure whatever protection you use can be safely removed later.

- Retract cylinders to protect the piston rods.

Left: Rusty chain. Right: Air blowout adapter.

These Things Need to Be Nice and Dry

Don’t risk water freezing in your ride. Be sure to drain, blow out, and/or vent:

- Water pipes (and pneumatic lines with moisture in them)

- Water pump housings

- Flanges with pooling water

- Oil filled volumes with moisture in them

- Even things like eye wash stations

Your Ride Is Not an Animal Shelter

Who doesn’t love a warm and dry place to live in the wintertime? Raccoons, rodents, and other furry friends sure do. They will make themselves comfortable in your ride or storage space and bring in food, chew and claw, and of course, use it as an outhouse. Worse, sometimes these critters get stuck and don’t come out.

So close off areas where you can.

You get the idea.

Power On or Off?

When you put these giants to bed, you might want to leave a nightlight on. There are components that need trickle power or the added warmth of a light bulb. Some PLCs need power to maintain the memory, so remember to record any season stats or settings before being powered down. Check also if some circuits need power to be left on to maintain battery life. Some batteries will die if you leave them unused for too long – even those ones in the emergency light signs. Certain batteries self-discharge with no load, and some circuits draw a constant trickle. Once these batteries fall below about 50% capacity, they may lose some ability to recover properly.

Your Spring Self Will Thank You

Before your ride enters hibernation, ensure you have what it needs when it’s time to “wake it up” in spring.

- Complete a spare parts inventory.

- List required maintenance tasks and service parts.

- Identify any upgrades/replacements for next year.

- Order parts and services now and not the week before spring.

Throughout the winter break, check up on your ride every 4 – 6 weeks, depending on your environment. Rotate the parts that should rotate during the season. Inspect for any changes in condition.

Preparing for a New Season: Waking Up Your Ride

With the welcoming sounds of spring, you’ll be preparing to “wake up” your ride and its system. That means removing debris, pressure washing, and evicting critters. Find the O&M manual for your ride and follow all instructions listed there.

Generally speaking though:

- Find the records and photos you took back in autumn and compare them to the condition now.

- Re-lubricate parts, even though the ride has not moved all winter.

- Refill drained systems slowly to prevent damage and ensure proper pressurization; look for air locks on any high spots of the piping system.

- Bump motorized systems to gradually get them moving.

- Follow a structured pre-season commissioning process and checklist to confirm readiness.

- Conduct cycle testing, both loaded and unloaded, to verify proper operation under different conditions.

Before putting patrons on the ride, test the equipment according to the procedures found in your O&M manual.

And now, after all your diligent prep work—and prayers for lots of sunshine—you’ll have a brilliant start to the new season.

Questions? Need more details? Contact me for anything related to water ride maintenance. I’d be happy to help.